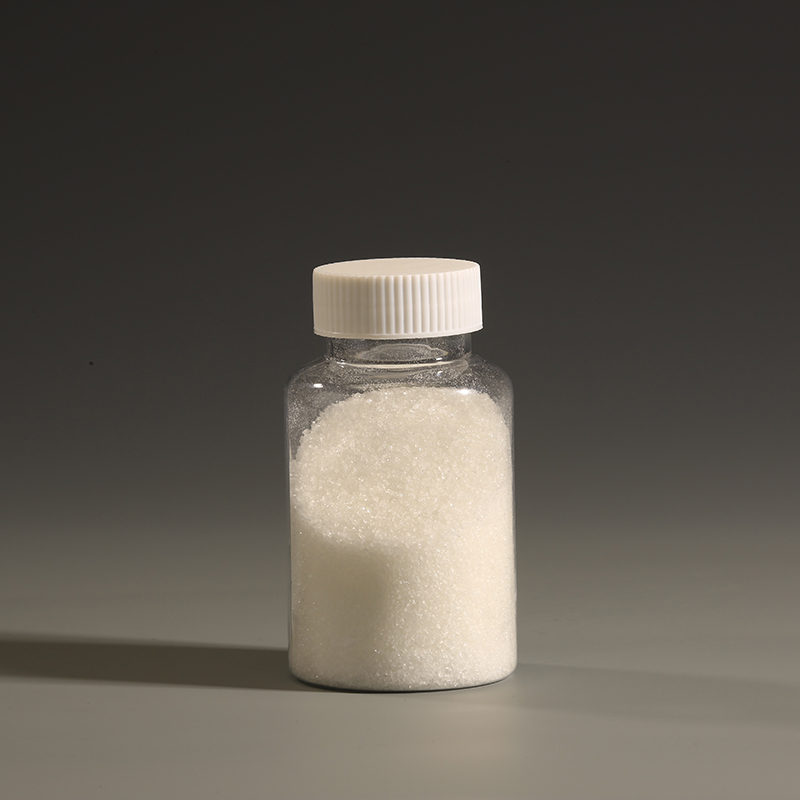

Polydiallyldimethylammonium chloride(PolyDADMAC) yog ib qho cationic polymer flocculant siv dav dav thiab ua lub luag haujlwm tseem ceeb hauv kev kho dej. PDADMAC feem ntau yog siv ua flocculant thiab qee zaum sib xyaw nrog algaecides. Tsab xov xwm no yuav piav qhia txog qhov zoo thiab qhov txiaj ntsig ntawm kev siv PolyDADMAC los ntawm cov yam ntxwv ntawm nws cov txheej txheem ua haujlwm, cov xwm txheej thov thiab cov tswv yim tshwj xeeb rau kev txhim kho kev kho dej kom zoo.

Cov yam ntxwv tseem ceeb ntawm PolyDADMAC

PolyDADMAC yog ib qho polymer molecular siab nrog ntau pawg cationic hauv nws cov qauv molecular, uas tuaj yeem nqus tau cov khoom me me thiab cov colloids hauv dej. Nws cov yam ntxwv tseem ceeb suav nrog:

1. Muaj zog cationicity: Nws tuaj yeem tshem tawm cov khoom me me uas raug tshem tawm hauv dej sai sai.

2. Kev yaj dej zoo: Nws yooj yim yaj rau hauv dej thiab yooj yim rau kev siv rau ntawm qhov chaw.

3. Kev ruaj khov tshuaj lom neegNws tuaj yeem tswj tau qhov ua tau zoo ntawm kev ua kom cov dej ntws zoo hauv ntau yam pH, qhov chaw oxidizing thiab qhov chaw ua haujlwm siab. PDADMAC muaj zog tiv taus chlorine.

4. Tshuaj lom tsawg: Nws ua tau raws li cov qauv kev tiv thaiv ib puag ncig thiab tsim nyog rau kev kho dej haus.

Mechanism ntawm kev ua haujlwm ntawm PolyDADMAC hauv kev kho dej

Nws ua rau cov khoom me me uas raug dai thiab cov tshuaj uas muaj cov nqi tsis zoo hauv dej tsis ruaj khov thiab ua rau lawv sib sau ua ke los ntawm kev ua kom tsis muaj zog hluav taws xob thiab kev sib txuas ntawm kev nqus. Nws muaj cov teebmeem tseem ceeb hauv kev tshem tawm cov xim, thiab tshem tawm cov organic.

PolyDADMACtxhim kho kev kho dej kom zoo dua los ntawm cov txheej txheem hauv qab no:

1. Kev them nqi tsis tu ncua

Cov khoom me me thiab cov colloids hauv dej feem ntau nqa cov nqi tsis zoo, uas ua rau muaj kev sib tsoo ntawm cov khoom me me thiab ua rau nws nyuaj rau daws. Cov pab pawg cationic ntawm PolyDADMAC tuaj yeem tshem tawm cov nqi tsis zoo sai sai, txo qhov electrostatic repulsion ntawm cov khoom me me, thiab txhawb cov khoom me me coagulation.

2. Kev cuam tshuam ntawm kev sib txuas lus

Cov qauv molecular ntev ntawm cov polyDADMAC uas muaj viscosity siab ua rau nws tsim tau ib lub "choj" ntawm ntau yam khoom me me, sib sau ua ke cov khoom me me rau hauv cov flocs loj dua, yog li ua kom cov dej noo zoo dua.

3. Ua kom muaj zog ntawm cov nyhuv ntes tau hauv internet

PolyDADMAC tuaj yeem ua kom lub "net structure" uas tsim los ntawm inorganic coagulant hauv kev kho dej kom ntes tau cov khoom me me, tshwj xeeb tshaj yog nyob rau hauv cov dej turbidity siab lossis cov dej muaj kuab paug heev.

Cov xwm txheej ntawm daim ntawv thov ntawm PolyDADMAC

1. Kev kho dej haus

PolyDADMAC siv ua flocculant los tshem tawm cov turbidity, cov khoom me me thiab cov organic teeb meem ntawm cov dej haus. Tib lub sijhawm, vim nws tsis muaj tshuaj lom thiab tiv thaiv ib puag ncig, nws tuaj yeem ua tau raws li cov qauv kev nyab xeeb dej haus.

2. Kev kho dej khib nyiab

Hauv kev kho dej khib nyiab hauv nroog thiab kev lag luam, PolyDADMAC feem ntau siv los txhim kho kev ua haujlwm ntawm cov dej khib nyiab, txo cov dej noo ntawm cov av nkos, thiab txo cov nqi khiav lag luam.

3. Kev ntxuav dej hauv kev lag luam

Hauv kev lag luam fais fab, petrochemical thiab lwm yam lag luam, PolyDADMAC yog siv rau kev ntxuav cov dej lag luam xws li dej txias thiab dej boiler kom txo cov kev pheej hmoo ntawm kev ua kom tawv thiab xeb.

4. Kev lag luam ntawv thiab textile

PolyDADMAC yog siv los ua kev pab khaws cia thiab lim dej kom txhim kho qhov ceev ntawm cov fibers thiab cov khoom sau hauv cov txheej txheem ua ntawv, thaum txo cov ntsiab lus ntawm cov khoom dais hauv cov dej khib nyiab.

Cov tswv yim rau kev txhim kho kev kho dej kom zoo nrog PolyDADMAC

1. Kev tswj hwm cov tshuaj kom zoo dua

Qhov ntau npaum li cas ntawm PolyDADMAC muaj feem cuam tshuam nrog qhov concentration, qhov loj me ntawm cov khoom me me thiab cov yam ntxwv ntawm cov khoom me me uas raug tshem tawm hauv dej. Kev ua kom zoo tshaj plaws ntawm qhov ntau npaum li cas los ntawm kev sim lub thawv tuaj yeem ua rau nws cov txiaj ntsig flocculation ntau tshaj plaws thaum zam kev siv ntau dhau uas ua rau muaj nqi ntau dua lossis kev ua qias tuaj ntawm dej thib ob.

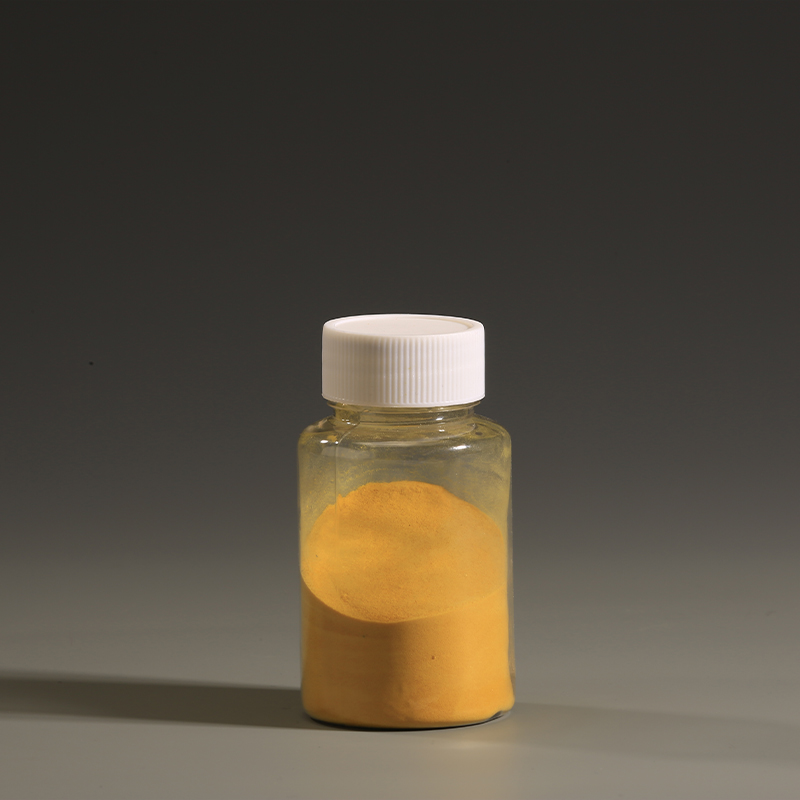

2. Cov nyhuv synergistic nrog cov inorganic flocculants

Kev siv PolyDADMAC ua ke nrog cov inorganic flocculants (xws li polyaluminium chloride thiab aluminium sulfate) tuaj yeem ua rau cov nyhuv flocculation zoo dua. Tom qab PolyDADMAC neutralizes qhov them ntawm cov khoom me me, cov inorganic flocculants ntxiv tsim cov flocs loj dua los ntawm kev nqus thiab kev tso dej.

3. Txhim kho qib kev ua haujlwm tsis siv neeg ntawm cov txheej txheem kho dej

Nrog kev pab los ntawm cov tshuab tswj tsis siv neeg, kev saib xyuas tiag tiag thiab kev hloov kho ntawm PolyDADMAC koob tshuaj tuaj yeem ua tiav los daws cov kev hloov pauv hauv kev kho mob zoo los ntawm kev hloov pauv ntawm cov dej zoo.

4. Txhim kho cov xwm txheej sib xyaw

Tom qab ntxiv PolyDADMAC, qhov sib tov kom zoo thiab lub sijhawm yuav ua rau nws cov khoom tawg thiab ua rau cov khoom sib xyaw zoo dua. Kev sib tov ntau dhau yuav ua rau cov khoom sib xyaw tawg, thaum kev sib tov tsis txaus yuav txo qhov sib tov.

5. Kho tus nqi pH

PolyDADMAC ua tau zoo tshaj plaws nyob rau hauv cov xwm txheej uas tsis muaj zog mus rau cov dej alkaline uas tsis muaj zog. Thaum kho cov dej uas muaj kua qaub ntau lossis alkaline ntau, kev kho tus nqi pH ntawm lub cev dej tuaj yeem txhim kho nws cov nyhuv flocculation.

Cov txiaj ntsig ntawm PolyDADMAC

1. Kev ua haujlwm zoo: Kev tsim cov flocs sai sai los txhim kho kev sib cais cov khoom khov thiab kua.

2. Ntau yam kev sivSiv tau rau ntau yam dej zoo, tshwj xeeb tshaj yog cov dej uas muaj cov av nkos ntau thiab muaj cov organic ntau.

3. Kev tiv thaiv ib puag ncig: Tsis muaj tshuaj lom thiab biodegradability, ua raws li kev tiv thaiv ib puag ncig.

Raws li ib qho kev ua haujlwm zoo heevcov khoom ua kom cov dej khov, PolyDADMAC muaj cov txiaj ntsig zoo hauv kev siv dej vim nws muaj zog cationicity, dej solubility zoo thiab siv tau dav. Los ntawm kev ua kom zoo dua qub thiab cov tswv yim ua haujlwm, nws cov kev kho mob zoo hauv kev ntxuav dej haus, dej phwj tuaj yeem txhim kho ntxiv.

Lub sijhawm tshaj tawm: Lub Kaum Ob Hlis-06-2024