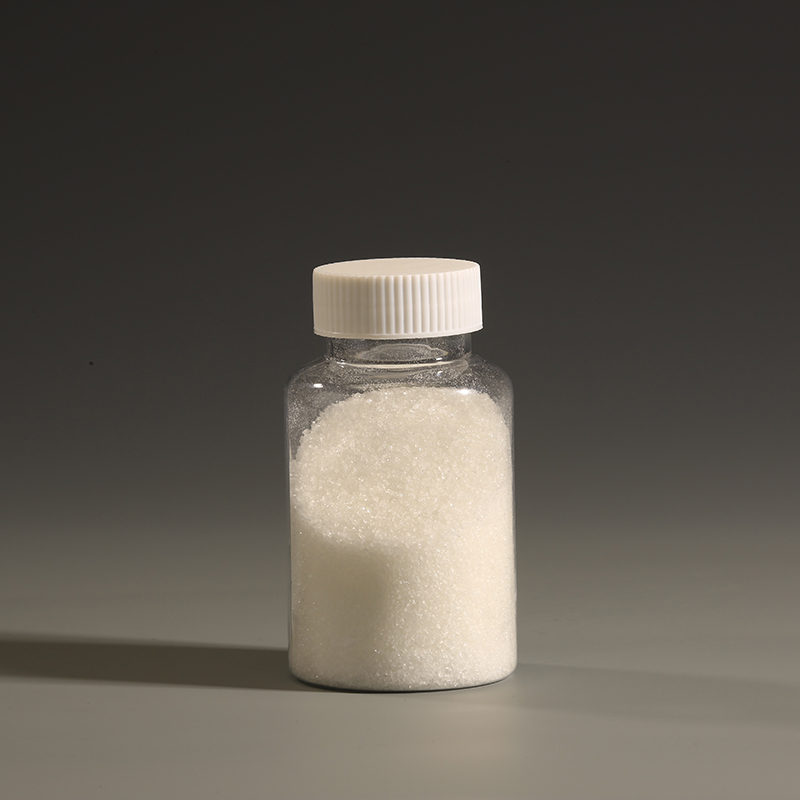

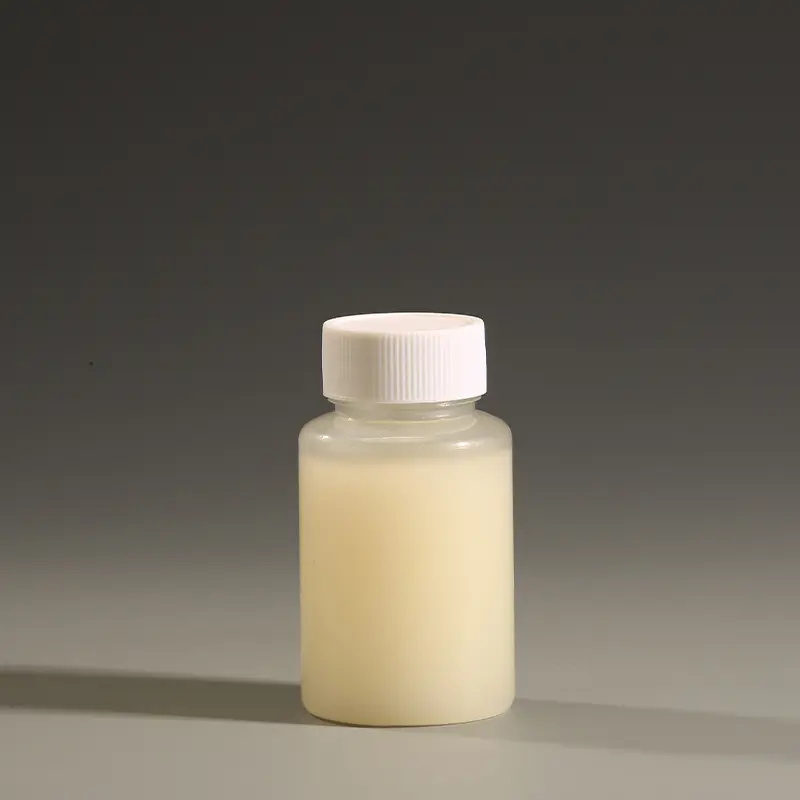

Polyacrylamideyog ib lo lus dav dav rau homopolymers ntawm acrylamide lossis copolymers nrog lwm cov monomers. Nws yog ib qho ntawm cov polymers uas yaj hauv dej siv dav tshaj plaws. Polyacrylamide muaj nyob rau hauv daim ntawv ntawm cov granules dawb thiab tuaj yeem faib ua plaub hom: non-ionic, anionic, cationic, thiab amphoteric ionic.

Cov ntawv thov ntawm Polyacrylamide hauv daim teb ua ntawv

Cov txheej txheem ua ntawv muaj ntau theem, suav nrog kev ua pulping, kev tshuaj ntsuam, kev ntxuav, kev ua kom zoo, thiab kev tsim. Thaum lub sijhawm ua cov txheej txheem no, ntau yam tsis huv xws li cov fibers, cov khoom sau, thiab cov npluas raug tsim. Yog tias cov tsis huv no tsis raug tshem tawm ntawm lub pulp, lawv tuaj yeem ua rau muaj teeb meem xws li cov dej ntws tsis zoo thiab cov ntawv tsis muaj zog. Polyacrylamide feem ntau yog siv ua cov khoom faib tawm, cov khoom pab khaws cia, cov khoom pab ntws, cov khoom sib xyaw, thiab cov neeg sawv cev ntsuas hauv cov txheej txheem ua ntawv.

Ⅰ. Cov tshuaj yaj tawm

Ntxiv cov tshuaj polyacrylamide dispersant thaum lub sijhawm ua ntawv tuaj yeem tiv thaiv kev sib sau ua ke ntawm cov fibers thiab txhim kho qhov sib xws ntawm daim ntawv. Qhov ntxiv me me tuaj yeem txhawb kev sib kis zoo ntawm cov fibers ua ntawv thiab ua tiav cov txiaj ntsig zoo ntawm daim ntawv. Nws kuj tseem tuaj yeem txhim kho qhov sib npaug ntawm cov pulp thiab qhov mos ntawm daim ntawv, thiab txhim kho cov khoom muaj zog ntawm daim ntawv. Nws yog qhov tsim nyog rau ntau yam khoom siv ntawv hauv tsev xws li daim ntawv so quav, phuam so tes, ntaub so ntswg ntsej muag, thiab lwm yam ntawv nyias nyias. Hauv qee lub Hoobkas ntawv, nws tuaj yeem hloov pauv Polyethylene Oxide (PEO) tag nrho.

Ⅱ. Kev Pab Txhawb Kom Khaws Cia

PAM feem ntau siv los ua ib qho kev pab khaws cia hauv kev lag luam ua ntawv kom nce tus nqi khaws cia fiber thiab txo cov dej phwj tuaj. Nws txoj cai ua haujlwm yog los tsim cov flocs loj nrog cov khoom me me, uas tuaj yeem tshem tawm yooj yim ntawm cov pulp los ntawm kev lim dej lossis kev tso dej.

Ⅲ. Kev Pab Cuam Dej Ntws

PAM kuj tseem tuaj yeem ua haujlwm ua ib qho kev pab cuam ntws dej hauv cov txheej txheem ua ntawv. Nws ua rau kom cov dej ntws ntau dua, ua rau cov ntawv tshem dej sai dua thiab ua haujlwm tau zoo dua ntawm lub tshuab ua ntawv. Qhov no pab ua kom ceev nrooj ntau lawm thiab txo kev siv hluav taws xob los ntawm kev luv lub sijhawm ziab ntawv.

Ⅳ. Tus Neeg Sawv Cev Loj

Qee zaum, polyacrylamide yog siv los ua tus neeg sawv cev rau kev ntsuas hauv kev ua ntawv los tswj kev nkag mus ntawm dej thiab lwm yam kua rau hauv daim ntawv. Qhov no pab ua tiav cov yam ntxwv xav tau xws li kev tiv thaiv dej thiab kev tuav cov kua mem, tshwj xeeb tshaj yog nyob rau hauv cov ntawv thov uas daim ntawv yuav tsum tiv taus cov dej noo lossis cov txheej txheem luam ntawv.

Ⅴ. Cov khoom ua kom cov dej khov

Thaum lub sijhawm kho cov dej khib nyiab hauv cov chaw ua ntawv, polyacrylamide tuaj yeem siv ua flocculant los tshem tawm cov khoom khov thiab cov pa phem hauv cov dej khib nyiab. Nws pab tsim cov khoom loj dua hu ua flocs, uas tom qab ntawd tuaj yeem tshem tawm tau yooj yim los ntawm cov txheej txheem sedimentation lossis lim dej. Qhov no pab txo cov pa phem hauv dej thiab txhim kho kev ruaj khov ntawm ib puag ncig ntawm kev lag luam ua ntawv.

Zuag qhia tag nrho, cov yam ntxwv ntawm polyacrylamide ua rau nws yog ib qho khoom siv tseem ceeb hauv kev lag luam ua ntawv, pab txhawb rau kev ua haujlwm zoo dua, cov khoom zoo, thiab kev ua tau zoo ntawm cov khoom ntawv. Kev siv polyacrylamide hauv kev ua ntawv npog tag nrho cov saw hlau kev lag luam ua ntawv, los ntawm kev tsim ntawv mus rau kev kho dej khib nyiab. Nws tsis tsuas yog txhim kho qhov zoo thiab kev tsim khoom ntawm ntawv, txo cov nqi tsim khoom, tab sis kuj ua rau muaj kev pab zoo rau kev tiv thaiv ib puag ncig.

Lub sijhawm tshaj tawm: Lub Peb Hlis-21-2025